For a number of years I've been making adaptor cables to convert from the proprietary Ferrari charger connector to the CTEK connector. This allows people to use the CTEK series of chargers to charge / battery tend their Ferraris. Ferrari rebrands the (lowest end) CTEK, and puts on thier proprietary connector, but many people would rather use one of the higher end / more sophisticated CTEK, or replace a dead Ferrari branded one, etc.

Using the Ferrari connector is much nicer than simply wiring the ring terminals to the battery, including:

- It is more convenient - the Ferrari connector is bolted to the vehicle, and so less fiddling around in the footwell.

- Much simpler - you simply plug in a connector, you don't have to unbolt panels and bolt ring terminals to the battery.

- Most importantly (to me at least), the Ferrari connector includes a "sense" wire. This means that the car will display an icon on the dashboard and refuse to start while the charger is connected, this prevents the embarrassing driving off while the charger is connected issue :-)

I make (and see these) cables, but I'm as happy for people to make their own (I'm somewhat OCD about making cables, and have over-engineered these. This means that it takes me around an hour per cable to make. The amount I sell them for isn't really worth my time, so I mostly make these for the good of the community).

If you have any questions, email me at

Parts:

- MBG4P-1 - DigiKey: SOU1192-ND $8.05ea - 4 Pin Souriau MBG Series Connector

- MBG4S-1 - DigiKey: SOU1196-ND $4.30ea - 4 Pin Souriau MBG Series Shell / Strain Relief.

- RC14M50K - DigiKey: SOU1970-ND $1.11ea (x 3) - Souriau 14AWG Machined Crimp Connector OR

- SC14ML1S6 - DigiKey: SOU1247-ND $1.62ea (x 3) - Souriau 14AWG Stamped Crimp Connector

- CTEK (56-384) - Amazon: LINK $9.99 - Comfort Indicator Clamps

- 18AWG strunded wire

- Various heatshrink

- Hotglue

I have provided part numbers for both machined (RC14M50K) and stamped (SC14ML1S6) contacts. The machined contacts are much nicer, but require a specific crimper head (S16RCM1450 $292) and handles (SHANDLES $125). The stamped ones work OK, and I'm using them in this tutorial because I don't really expect people to buy $417 worth of crimper just to build one cable. Actually, I'm using the stamped connectors meyelf at the moment, because my S16RCM1450 head broke, and the replacement is backordered till 1/8/2016. Whatever contacts you choose, you should buy a bunch of them - Digikey shipping is quite expensive, and you may miscrimp some.

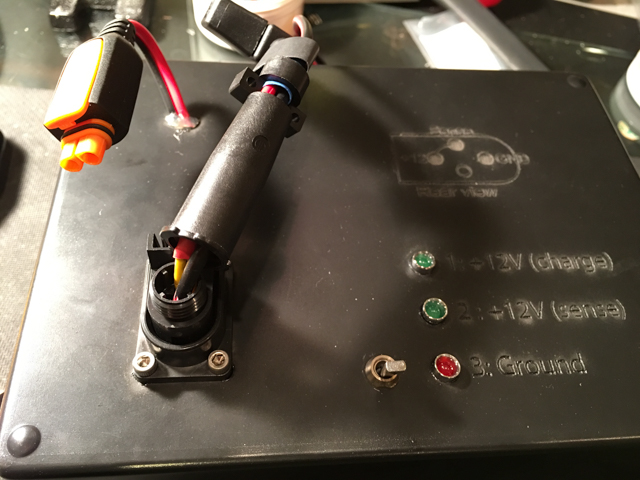

Pinout:

- Pin 1: +12V

- Pin 2: Sense

- Pin 3: Ground

- Pin 4: N/C

When Pin2 is raised to +12V to illuminate the warning icon on the instrument panel and prevent the vehicle from starting.

Instructions:

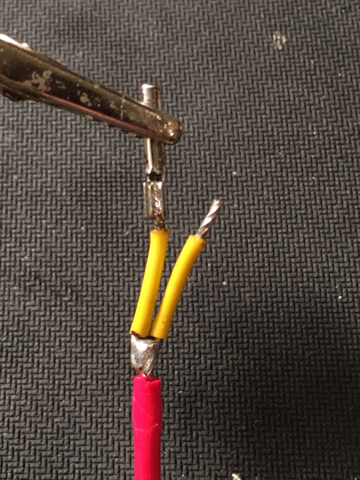

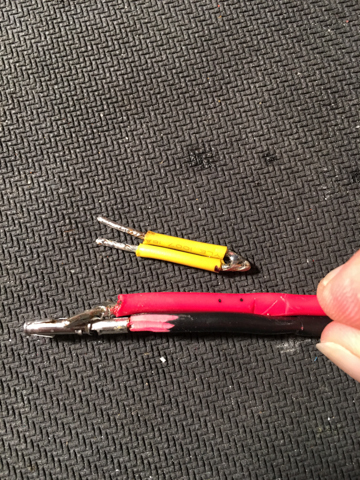

Start off by removing the clamp connectors - prise off the plastic protectors, and then unsolder the clamps. Do not cut off the clamps, or the remaining wire will be too short to easily insert with the strain relief and connector.

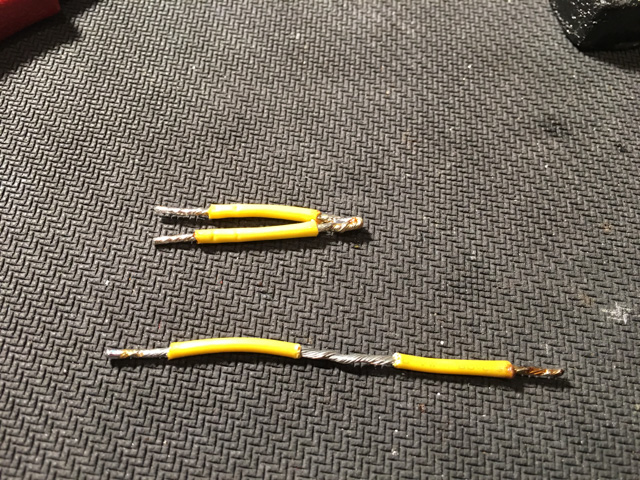

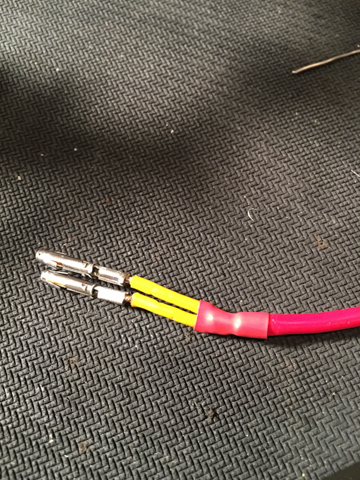

Crimp a contact onto the (tinned) black (ground) wire. As I mentioned, I'm a little anal about making cables, and so I go a little overboard. This is how I do mine:

Add a tiny bit of flux into the connector cup, and then add some solder into the cup. Then put in the tinned cable, and heat if from the bottom (to make sure that solder fully wets / flows. Then crimp (with good quality, ratcheting crimper with the correct sized head, for example a Wiha 436) the connector on, and finally flux over the top of the crimp and solder over the top. I've tested this system, and it provides me a much stronger (and lower resistance) connection than crimping or soldering by itself.

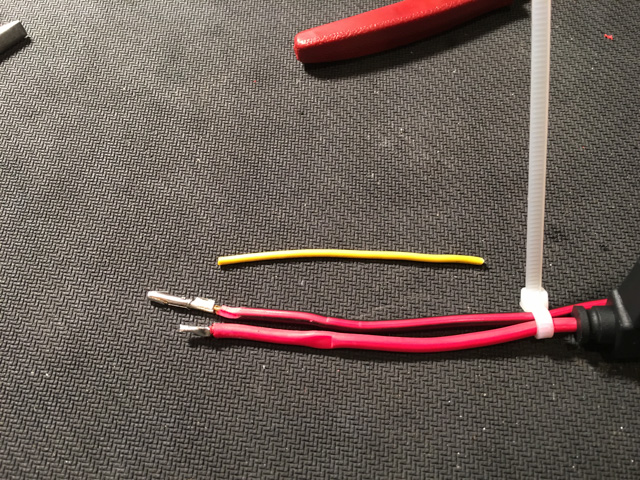

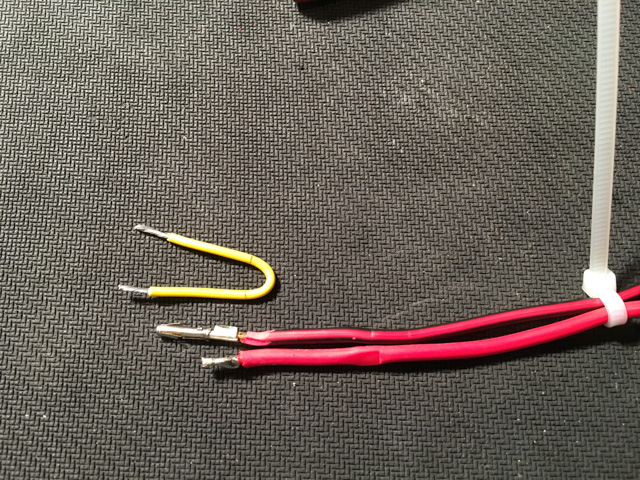

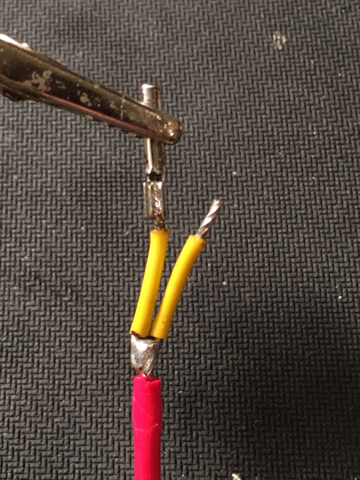

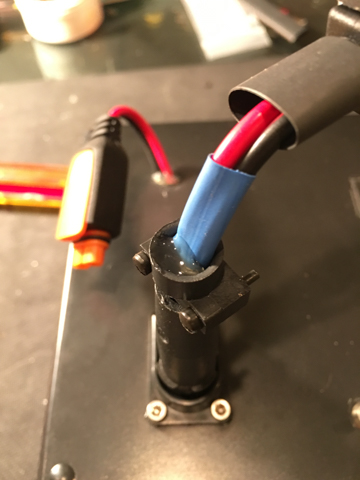

Next, cut a 3.5" piece of 16AWG stranded wire. Fold this in half, and mark 0.25" down from the fold. Unfold this, score round the insulation and then cut down the length of the insulation, and remove this piece. Then trim ~0.25" of insulation from each end.

Now, fold the cable again, liberally flux it and then tin the center and ends. Make sure to not have the insulation touching when tinning the center or it will stick. Now, lay the folded, tinned 16AWG wire next to the carger cable, and carefully align them. I ziptie the red and black together to make sure that they are nicely aligned. Now, mark and cut the red (12V) cable, making sure to take into account the length of the wire going into the contacts, and enough to solder - you want the wires to be the same length so that they have the same tension. Solder the contacts onto the ends of the 16AWG wire, using the technique above.

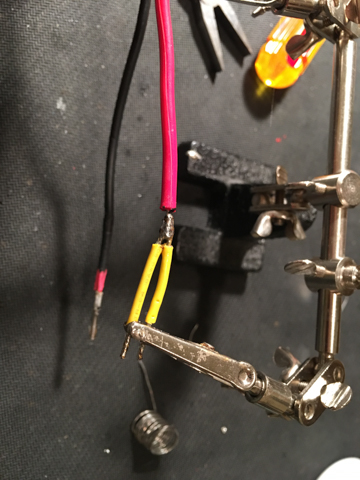

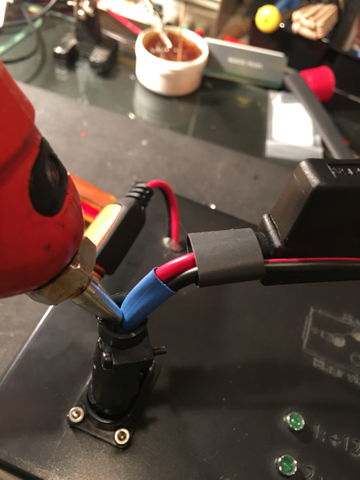

Now solder the charger wire onto the 16AWG jumper, and put on a bit of heatshrink.

When shrinking the heatshrink, I use a hot air surface mount solderer. This works much better than a heat gun (or lighter!), because it makes a much more focused stream of air - without this, you rish melting the insulation.

Next, slide on some heatshrink and don't forget the shield, or you will become very sad. :-)

Now, insert the contacts into the shell, making sure that the contacts have fully seated. This will be quite fiddly (especially if you included some heatshrink to go over the back of the strain relief), and you will be glad that you unsoldered the clamps, because this gives you an extra ~0.25". I use a pair of needle nosed pliars to push the wires from the back. Now, test the pinouts to make sure you have it all right. I have built a test jig to allow me to accuratly and quickly test mine, but a multimeter will work.

Once you have triple checked the pinouts and that there are no shorts, squeeze some hotglue into the back of the connector shell, slightly overfilling it, and then quickly screw the strain relief on. This will tightly hold the cables, provide good strain releif, help keep things dry (and corrosion free), and prevent it unscrewing.

Now, add some more hotglue in through the cutout in the strain relief, and quickly screw the cable clamp onto the back. Some hotglue will squish out, trim this off with an xacto knife, and then hit it with a heatgun to clean it up. Now, put some more glue in through the back of the strain relief and slide the last piece of heat-shrink over the back and shrink it on.

Finally, test it one last time, and you are done!

You could do this all with much less work, by cutting a bunch of corners (like just crimping the contacts, or splicing wires together, or not using the correct crimper), but, if you are going to bother doing it at all, you might as well do it right.

Because of the snow and cold we've had this winter I wasn't able to take my 599 out, or even spend some time in the gararge detailing it.

This made me antsy, and so I decided to finally take care of a minor issue that had been irritating me for a long time -- the paint was shipping off the keyfob. This is a common issue, and usually starts right around the hole where the key attaches to the keyring.

Here is a small writeup for others:

Step 1: Disassemble key.

The back (with the emblem) pops off easily; insert a small screwdriver in the slot and pop it off. While it is off, you might want to replace the battery and save yourself from later issues. The front also snaps off, but needs a thin blade inserted between the black casing and the front to pry it off. Getting the rubber button bits out needs a small blade, and you carefully pry it out. It didn't seem to be glued, simply press fitted.

Step 2: Remove the emblem

Getting the emblem off was easy enough. I initially tried wedging a blade under it, but it seemed clear that that would scratch either it, or the caseing. I ended up drilling a small hole through the back of the casing, and then simply pushing it out from behind (obviously, don't drill through the emblem itself!)

Step 3: Sand off old paint

I used some 600 grit paper, placed on the sponge side of a (dry) Scotch-Brite Non-Scratch Scrub Sponge. This seemed to have just the right amount of "give" to remove the paint without changing the shape of the key.

Step 4: Prepare for paint.

After cleaning the sanding residue off with isopropyl alchohol I prepared them for paint. It was too cold to paint them outside or in the gararge, and so I did it in the utility room in the basement. I raised them off the paper with some playdough and then gave them a quick spray with SEM 39863 Plastic Adhesion Promoter.

Step 5: Paint

I gave them a quick spray with white primer. Without this, the red would come out too dark, and not "pop". I then gave them 8 coats of Ferrari Rosso Corsa / PPG 322 paint, goodly waiting between each coat for it to dry fully. Ok, that's not actually true, I got impatient and only waited 20 minutes between coats. This means that the parts are taking forever to fully dry, and are still not done.

I recently traded in my Lamborghini Murcielago and replaced it with a Ferrari 599BGP Fiorano.

I'm really enjoying how much more civilized it is than the Murcielago. I can get in it and just drive, no worrying about what will happen if there is a raindrop, it is a coupe, and so is much quieter, the visibility is great, and because it is rear-wheel drive (not all wheel drive) you can have some more fun with it :-)

It is, of course, Rosso Corsa over tan.